Production

The complete production of Miss accessori is located in Prato-Montemurlo ensuring that all the scarves shawls, ponchos hats and gloves produced are entirely "Made in Italy".

The Prato-Montemurlo area has always been known for its textile productions of the highest level.

An advanced computer system has been implemented in order to monitor each step of the production.

The yarn

In order to better plan the productions Miss Accessori can count on a yarn warehouse of 1000 sqms where a big variety of yarns is stored. Many typologies and compositions are always available for any kind of request. Synthetic fibers, such as acrylics and mixed acrylics are used as well as most nobler fibers , such as wool or wool blends up to cashmere. In order to guarantee the quality of the productions, the yarn is controlled in every aspect before being put into work.

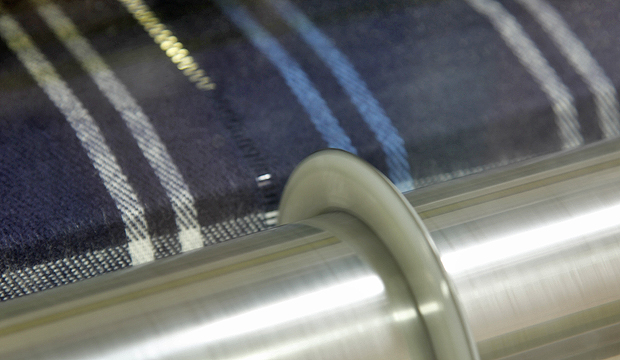

Heddle and jacquard looms

This is an important part of the production. During the years Miss Accessori has increased its production capacity by adding to the existing traditional looms, the more complicated and high tech jacquard ones which give the possibility to propose new designs and new constructions in accordance with markets demands. Designing and study is done internally so Miss Accessori is able to respond to customers requests with immediate and personal developments. Big attention is dedicated to the control of the fabrics which have to meet the quality standards that Miss Accessories expects from its productions.

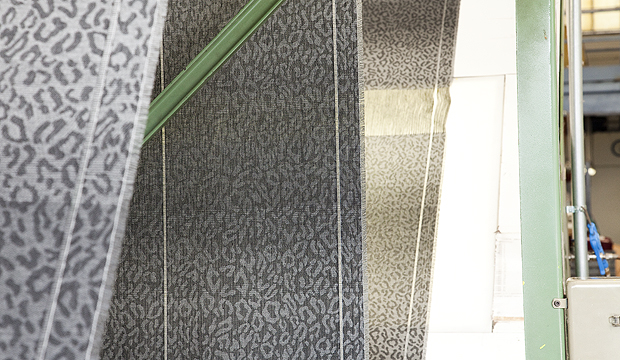

Crochet machines

This department is one of the flagships of the production of Miss Accessori. A big variety of fancy yarns are used leading to the creation of new particular weaves and colour effects. The entire production process is integrated with a computer system and advanced control, always guaranteeing the quality of the items made. Innovations and continuous investments made year after year, have made this department leading in the production of “crochet” and “rachel” articles.

The finishing house

Before being cut and packed, our products have to go through this department and undergo the process of finishing in to order to achieve the correct softness and become pleasant to touch. The correct hand is mandatory feature for a scarf Made in ltaly by Miss Accessori. After being checked and approved the fabric will be brushed – washed - ironed and cut and then sent to the headquarters for the final packaging and inspection before being shipped to customers all over the world. The status of each order can be determined in any moment. Thanks to our computer system we are able to control each production process in any time.

Shipping department and quality inspection

This department is responsible that all orders are correctly packaged in accordance which each customers requirement. Before shipping the goods are subject to a final inspection to verify the correctness of the works carried out and the quality of the articles. As for all other production departments the computer system in place allows a constant control of the status of the orders and the number of goods ready in the warehouse. Now the goods are ready to be sent to customers all over the world at the end of a long transformation process in which passion and quality have been the protagonists. Our scarf now is ready to be worn by the final customer.